What is Molybdenum Steel? A Beginner’s Guide

What is molybdenum steel? It’s a type of steel alloy that contains a small amount of molybdenum. This steel is used in various applications due to its high strength-to-weight ratio, good corrosion resistance, and high hardness.

In this article, I’ll provide you with all the information you need to know about molybdenum steel.

Check out our new cookbook

Bitemybun's family recipes with complete meal planner and recipe guide.

Try it out for free with Kindle Unlimited:

Read for freeIn this post we'll cover:

Unraveling the Wonders of Chromium Molybdenum Steel

Let me tell you a story about a metal that’s been making waves in various industries. This superhero of the steel world goes by the name of Chromium Molybdenum Steel, or Chrome Moly for short. What makes this low alloy steel so special? Well, it’s all in the elements, my friend.

Chrome Moly is a unique blend of two key elements: chromium (Cr) and molybdenum (Mo). These elements, when combined, produce a metal that’s got some pretty impressive benefits. For example, Chrome Moly has the ability to:

- Resist corrosion, which means it’s perfect for heavy-duty applications where other metals might fail

- Increase tensile strength, making it a top choice for construction and heavy equipment

- Maintain its hardness at high temperatures, which is crucial for applications like oil and gas production

Why Chrome Moly is the Life of the Party

You see, when chromium and molybdenum are added to steel, they work together to create a metal that’s got some serious advantages over your standard, run-of-the-mill steel. Here are some reasons why Chrome Moly is the life of the party:

- It’s got a higher strength-to-weight ratio, which means you get more bang for your buck

- Its uniform hardness makes it a dream to work with, whether you’re forming, cutting, or welding

- It’s widely used in a variety of industries, from automotive to aerospace, proving that it’s got the chops to handle just about anything

Chrome Moly: The Jack of All Trades

Now, you might be thinking, “Sure, Chrome Moly sounds great, but what can it actually do?” Well, let me tell you, this metal is a true jack of all trades. Here are some examples of its many applications:

- In the automotive industry, it’s commonly used for crankshafts, gears, and connecting rods

- In construction, it’s the go-to choice for heavy-duty equipment like cranes and bulldozers

- It’s even found in the world of sports, where it’s used to make bicycle frames and golf clubs

Chromium Molybdenum Steel: The Secret Ingredient for Success

So, what’s the secret to Chrome Moly’s success? It’s simple, really. By adding just a small amount of chromium and molybdenum to steel, you get a metal that’s:

- Extra strong, thanks to its increased tensile strength

- Highly resistant to corrosion, which means it can handle the elements like a champ

- Able to maintain its properties at high temperatures, making it perfect for high-stress applications

Unraveling the Characteristics of Molybdenum Steel

Let me tell you, molybdenum steel is no ordinary metal. When molybdenum is added to steel, it creates a super-strong and hard material that can withstand some serious wear and tear. This is all thanks to the little molecule of molybdenum, which enhances the steel’s:

- Strength

- Hardenability

- Weldability

- Toughness

- Elevated temperature strength

- Corrosion resistance

These characteristics make molybdenum steel a popular choice for various applications, including those that require a higher level of durability and resistance to corrosion.

Atomic Composition: A Transition Metal with a Twist

Molybdenum is a naturally occurring transition metal, known for its unique atomic structure. It consists of several isotopes, each with a different atomic mass. The most common and stable of these isotopes is molybdenum-98, which comprises about 24% of naturally occurring molybdenum. Other isotopes include:

- Molybdenum-95, which undergoes beta decay and is used in nuclear imaging applications

- Molybdenum-99, a synthetic radioisotope used in medical imaging

These isotopes give molybdenum its distinct characteristics, such as its resistance to oxidation and its ability to form cations with various oxidation states.

Melting Point and Thermal Expansion: Hot Stuff!

Molybdenum steel has a higher melting point than standard steel, making it perfect for applications that involve high temperatures. This elevated melting point is a result of the addition of molybdenum, which also affects the steel’s thermal expansion. Molybdenum steel has:

- A higher melting point than pure steel

- Lower coefficients of thermal expansion

These characteristics make molybdenum steel ideal for applications that require materials to withstand high temperatures without losing their shape or strength.

Corrosion Resistance: A Metal That Stands the Test of Time

One of the most impressive characteristics of molybdenum steel is its resistance to corrosion. This is due to the unique chemical properties of molybdenum, such as its electronegativity and its ability to form stable oxidation states. Molybdenum steel:

- Does not visibly react with oxygen at room temperature

- Shows a weak inclination to form aqueous corrosion products

- Can be controlled in gaseous environments through the formation of diatomic species with unpaired electrons

These properties make molybdenum steel a go-to choice for applications that require materials to resist corrosion and maintain their strength over time.

Commercial Production: The Molybdenum Steel Patent

The production of molybdenum steel is carefully controlled and involves a patented process. This process ensures that the resulting steel meets the strict ASTM standards for quality and performance. Some key aspects of molybdenum steel production include:

- The addition of molybdenum to cast steel or iron

- The application of specific heat treatments to enhance the steel’s properties

- The use of controlled cooling processes to achieve the desired hardness and strength

Unleashing the Power of Chrome Moly in Various Applications

As a car enthusiast, I’ve always been fascinated with the materials that go into making high-performance vehicles. Chrome moly steel has been a game-changer in the automotive and racing industries, providing that extra edge of strength and durability. Some of the common applications include:

- Tubing for roll cages in race cars, offering higher strength and lighter weight than standard steel

- Clutch and flywheel components, where its resistance to wear and high-temperature tolerance come in handy

- Tie rods and machine shafts, benefiting from the alloy’s increased tensile strength

Powering the Energy Sector

Working in the energy sector, I’ve seen firsthand how chrome moly steel plays a crucial role in both fossil fuel and nuclear power plants. Its high-temperature and pressure resistance make it an ideal choice for:

- Furnace equipment, where it can withstand extreme heat and pressure

- Conveyors and chain links, providing strength and durability in heavy-duty applications

- Drill collars, where its resistance to wear and corrosion is essential

Soaring High in the Aerospace Industry

As an avid aviation fan, I’ve always been amazed at the engineering marvels that take to the skies. Chrome moly steel has found its way into various aircraft applications, such as:

- Fuselages, where its strength-to-weight ratio is critical for maintaining structural integrity

- Aircraft gas tubing, benefiting from the alloy’s corrosion resistance and high-pressure tolerance

- Miscellaneous tooling, where its hardened surface and wear resistance prove invaluable

Reinforcing the Construction Industry

Having spent some time in the construction field, I can attest to the importance of using strong and durable materials. Chrome moly steel has become a popular choice for:

- Heavy equipment and machinery, where its strength and resistance to wear are essential

- Crankshafts and shafts, where its high tensile strength and toughness come into play

- Molds and other forming equipment, taking advantage of its ability to withstand high temperatures and pressures

Pedaling Forward in the Bicycle World

As a cycling enthusiast, I’ve always appreciated the innovation that goes into creating lightweight and strong bicycle frames. Chrome moly steel, or chromoly as it’s commonly known in the cycling world, has become a popular choice for:

- Bicycle frames, where its strength-to-weight ratio provides a stiffer and more responsive ride

- Tubes and tubing, where its corrosion resistance and high strength make it an ideal choice over aluminum or mild steel

Why Chromium Molybdenum Steel Knives are a Cut Above the Rest

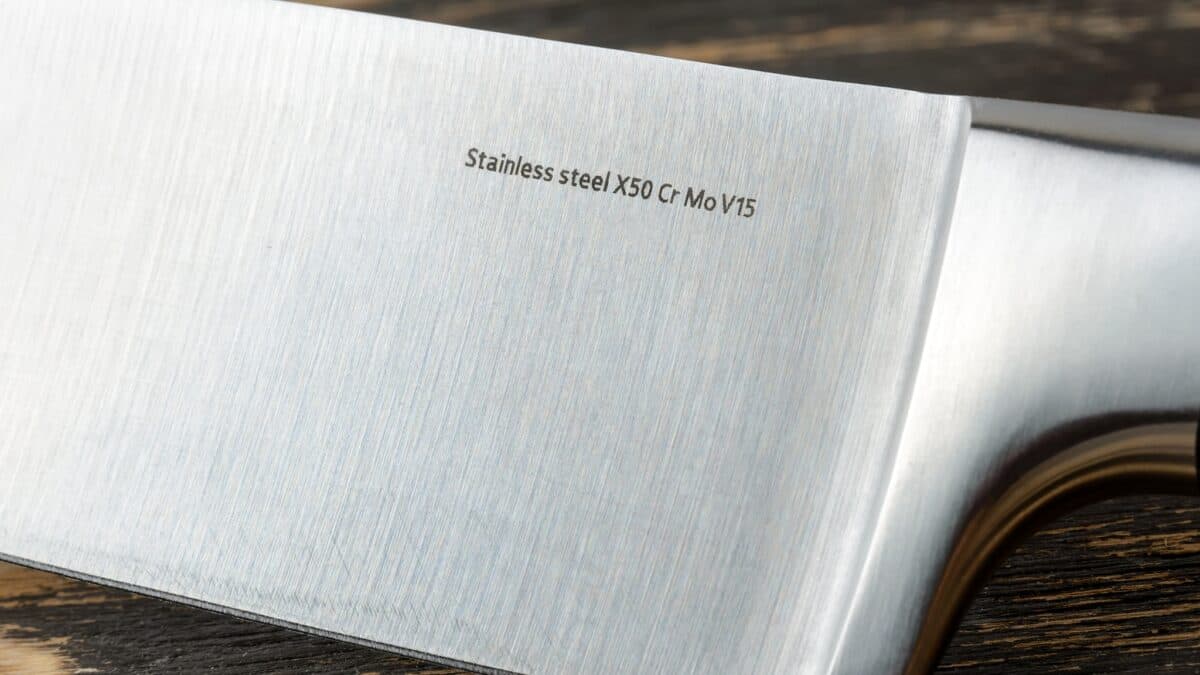

As a hobby cook and a first-time buyer of Japanese knives (here are my top picks for the most common kitchen tasks), I was on the lookout for a knife that would not only be affordable but also provide great performance. Enter Chromium Molybdenum Steel knives. These blades are made from a special mix of steel that contains chromium, molybdenum, and vanadium, which provides increased resistance to wear and corrosion. The addition of carbon and iron further enhances the blade’s toughness and durability. I was pleasantly surprised to find that these knives could stand up to the rigors of regular use without compromising on quality.

Sharp Edges and Easy Maintenance: A Match Made in Culinary Heaven

One of the most important aspects of a good knife is its ability to maintain a sharp edge. Chromium Molybdenum Steel knives are highly regarded for their ability to hold an edge and are surprisingly easy to re-sharpen. I found that even with basic sharpening skills, I could keep my knife in tip-top shape. The stainless steel mix also contributes to the blade’s resistance to rust, making it a practical and functional choice for any home cook.

Affordable without Compromising Quality

As a first-time buyer, I was on a budget, but I didn’t want to compromise on the quality of my kitchen knives. Chromium Molybdenum Steel knives offer a great balance between affordability and performance. With a wide range of prices, there’s a knife to suit every budget, from the low-end to the more expensive options. I discovered that even the more affordable options provided great performance and durability, making them an excellent choice for any hobby cook.

Design and Features: A Touch of Tradition Meets Modern Innovation

Chromium Molybdenum Steel knives come in a variety of types and styles, catering to different users and preferences. Some of the features I particularly appreciated include:

- Pakkawood handles: These are made from impregnated wood, providing a traditional look and feel while enhancing hygiene and durability.

- Bolsters: Many knives in this series feature bolsters for improved balance and safety.

- Wide range of sizes and styles: From small paring knives to large chef’s knives, there’s a Chromium Molybdenum Steel knife to meet every culinary need.

Highly Recommended by Knife Makers Around the World

When it comes to choosing a new knife, it’s always a good idea to look for recommendations from experts in the field. Chromium Molybdenum Steel knives are highly regarded by knife makers around the world, including renowned brands like Misono. Their comprehensive range of knives is designed to meet the highest standards of quality and performance, making them a top choice for both hobby cooks and professional chefs alike.

Conclusion

So, there you have it- everything you need to know about Molybdenum steel. It’s a great steel to have in your toolbox, especially for heavy-duty applications like construction and manufacturing.

You can’t go wrong with Molybdenum steel, especially when it’s been properly hardened and tempered. So don’t be afraid to explore the possibilities!

Check out our new cookbook

Bitemybun's family recipes with complete meal planner and recipe guide.

Try it out for free with Kindle Unlimited:

Read for freeJoost Nusselder, the founder of Bite My Bun is a content marketer, dad and loves trying out new food with Japanese food at the heart of his passion, and together with his team he's been creating in-depth blog articles since 2016 to help loyal readers with recipes and cooking tips.